2.3 billion people worldwide still lack access to clean cooking, relying on polluting fuels like wood, charcoal and animal dung.

Since 2010, Asia and Latin America have enabled 700 million people to switch to modern cooking methods, with 70% using LPG.

A new roadmap from the International Energy Agency (IEA) offers a realistic, cost-effective strategy to eradicate this major source of energy poverty and human suffering across sub-Saharan Africa by 2040. The roadmap shows that universal access to clean cooking is achievable within 15 years if African countries adopt proven strategies already implemented across other regions.

Approximately 1 billion of the 2.3 billion people globally without access to clean cooking are in Africa. LPG is a critical part of the solution. Since 2010, LPG has helped provide clean cooking access to over 1 billion people. Based on our analysis, we see another billion people gaining access to clean cooking thanks to LPG in a pathway that provides universal access to clean cooking globally by the end of the decade. LPG is a proven, scalable solution that can rapidly reach these people, and we need to continue our efforts.”

Daniel Wetzel, Head of the Tracking Sustainable Transitions Unit, IEA

LPG & clean cooking

LPG is non-toxic, efficient and already widely used for heating, cooking and transport.

Emissions

LPG emits ~80% less CO₂ than firewood. Following the IEA’s global clean cooking vision would cut 1.5 gigatons of CO₂-equivalent emissions by 2030, the same as the entire aviation and shipping sectors emit annually combined. Switching from firewood to LPG can cut CO₂ emissions by 170-415 million tonnes p.a., equivalent to the total emissions of the Netherlands or the UK.

Preventing Deforestation

Each 13 kg LPG cylinder used prevents the destruction of ~6 m² of forest. At scale, switching to LPG could help prevent the annual loss of forests the size of Ireland, conserving critical ecosystems and protecting food sources like fruit-bearing trees often cut for fuel. Transitioning 268 million households to LPG could prevent up to 2 million hectares of deforestation p.a., or 40% of global net deforestation.

Portability

LPG is highly portable, making it one of the most practical energy solutions. It can be stored, transported and used in cylinders of different sizes or in bulk tanks for larger users. LPG’s flexibility means it can reach remote areas, providing households, businesses and communities with reliable access to modern energy for a wide range of applications.

Efficiency

LPG transfers up to 60% of its energy to the cooking pot, 4x more efficiently than firewood.

Health

Household air pollution was responsible for an estimated 3.2 million deaths p.a., including over 237 000 deaths of children under the age of 5.

Gender Inequality

Women and girls often spend 18 hours per week, collecting fuel and cooking, limiting opportunities for education, employment and rest. In many regions, women also face increased risks of violence while collecting fuel far from home.

Spotlight – Sub-Saharan Africa

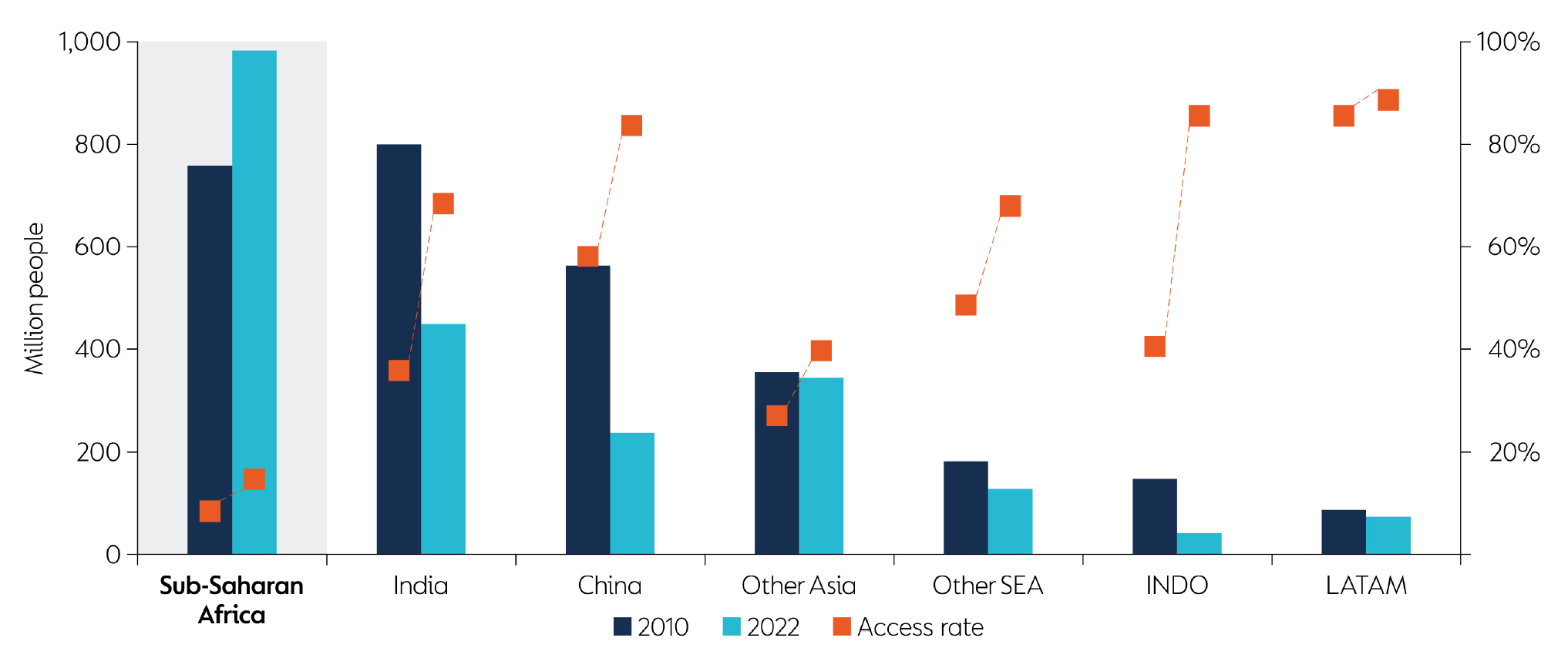

Sub-Saharan Africa is the only region that has seen an increase in population without access to clean cooking since 2010.

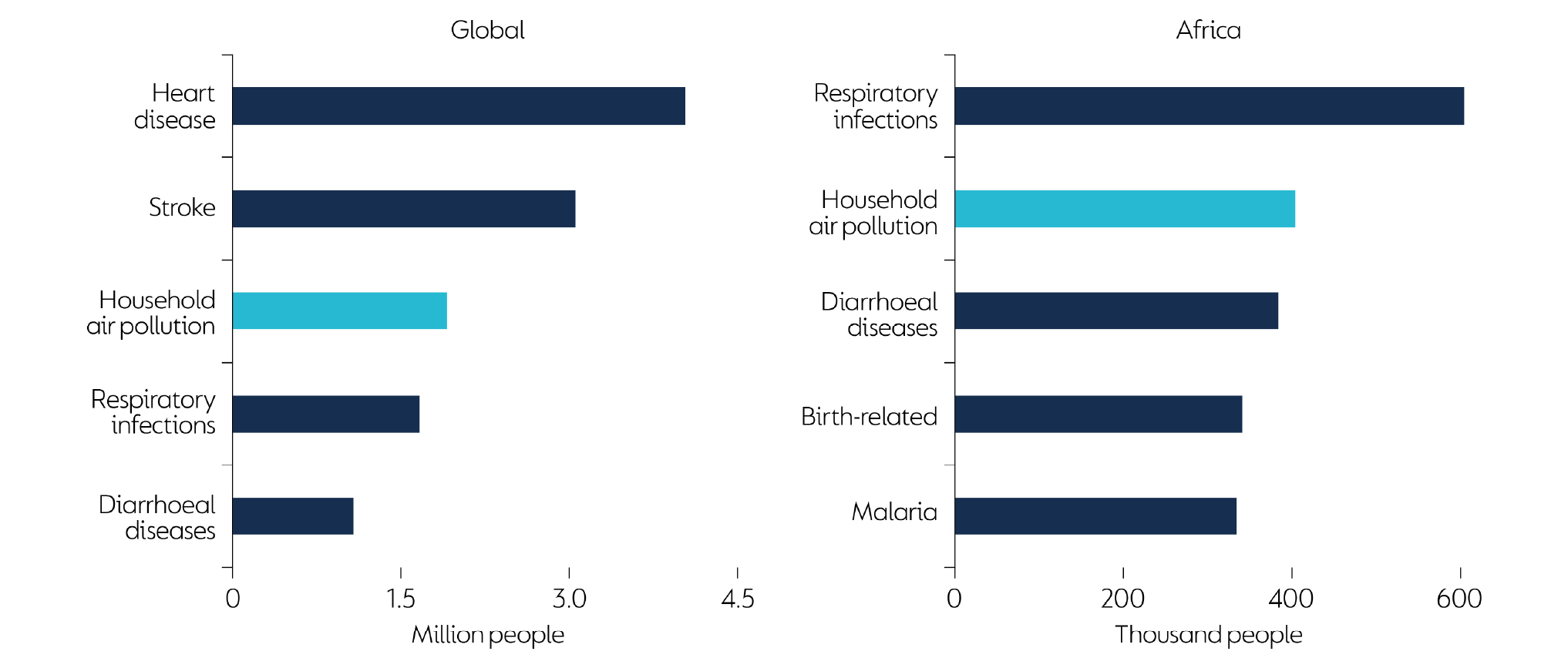

Africa suffers from the highest HAP-related mortality rate…

Deaths from household air pollution per 100,000 people, 2021

…where it is the 2nd leading cause of premature deaths amongst women and children

Annual deaths by cause amongst women and children

Clean cooking access in Africa has increased, but less than biomass…

Change in population primarily cooking by fuel, 2015-2022

…and has been more than offset by African population growth the past decade

Access rate and population without access to clean cooking by region, 2010-2022

Fleet operations

We operate one of the youngest and most fuel-efficient fleets in two of the shipping industry’s most environmentally progressive segments. Since 2020, we have invested approximately $1.3 billion in cleaner alternative fuel technologies, energy-saving innovations and the construction of new ultra-efficient vessels.

Petredec remains committed to owning the youngest, cleanest fleet of ships and trucks, and to investing in lower-emission transport solutions and renewable energy sources for its terminals wherever possible.

Fleetwide sustainability measures and initiatives

Equipment Upgrades

- Dual Fuel Engines and Deck Tanks reduce Well-to-Wake GHG emissions by 17%.

- Shaft Alternators increase energy efficiency.

- Air Guard Stern Tube Seals prevent oil leaks into the sea.

- Centrifugal Oily Water Separators improve

oil removal in discharge water. - Synthetic ropes replacing wire ropes: safer for crew, eliminates grease pollution.

- LED lighting and variable speed fans/pumps on new vessels, retrofitted to older ones.

Fuel Efficiency and

Waste Reduction

- X8 Silicone Paint to reduce hull resistance

and fuel consumption. - Propeller painting to reduce fouling

and metal loss from polishing. - Garbage compactors for efficient waste handling.

- Mass Flow Meters for accurate

fuel consumption tracking. - Fuel Additives to minimise sludge

and improve combustion.

Remote Monitoring and Performance Optimisation

- Wärtsilä FOS for voyage/weather routing

and remote engine monitoring. - MAN’s energy solutions: Primeserve, Engine Vault, Eco Torque.

- Delayed startup in lower sea water temperatures

to reduce energy use. - Enhanced cargo line insulation for heat loss reduction.

- Remote monitoring of cargo plant and close tracking of running hours.

Contemplated Future Initiatives

- Hard Coatings – Biocide-free alternative to silicone paint; lasts ten years, reducing the need for blasting at dockings.

- Waste Heat Recovery – Converts exhaust and cooling water heat into electricity as heavy fuels are phased out.

Onshore operations

Petredec is committed to advancing sustainability across its onshore operations through targeted initiatives that drive efficiency, reduce emissions and protect natural ecosystems. A cornerstone of this effort is our ambition to reduce overall energy consumption by 10%, an objective we aim to achieve through optimisation of existing equipment and processes. This includes the introduction of auto-shutoff functions and timers on electrical equipment wherever feasible, ensuring energy is only used when needed and helping to cut unnecessary consumption.